Impact extrusion is a technique that uses a press to produce metal goods and objects. The press used can either be mechanical or hydraulic. However, a metal slug needs to be pressed with the press via a die. When the metal slug goes through the die, it bends. This process enables businesses engaged in manufacturing to produce new goods and items identical in size and shape to the dye they use. Read More…

At Chicago Nut & Bolt, we specialize in manufacturing high-quality cold headed parts tailored to meet the most demanding industrial specifications. With decades of experience in fastener production, we have built a reputation for delivering precision-engineered components that perform reliably in critical applications.

Global manufacturer Stalcop specializes in the manufacturing of cold headed parts. Stalcop can meet your needs with specialty solutions, combining processes with secondary operations such as CNC machining and assembly. With over 100 years combined experience, count Stalcop for quality and lower prices! Stalcop serves its customers by offering products and services that are consistent and timely.

At Precision Metal Components, we specialize in manufacturing high-performance cold headed parts that deliver superior strength, precision, and reliability across demanding industries. Through advanced cold heading technology, we shape metal with exacting accuracy while minimizing material waste and improving structural integrity.

Here at NSK Industries, Inc. we are a turnkey manufacturing which means we will supply your cold forming needs with a short amount of lead time. Our company manages four facilities and we strive to be an unsurpassed supplier. We have the background and production lines that can get your projects done regardless of complexity. We are eager to adhere to your specifications. Please visit our website ...

More Impact Extrusion Manufacturers

Working Principle of Impact Extrusion

Impact extrusion is a high-efficiency cold forming process widely utilized in modern metalworking industries for manufacturing precision metal components. The process relies on either a mechanical or hydraulic press to shape a metal slug—typically aluminum, steel, brass, or other ductile metals—into a desired form. The press operates by rapidly lowering a punch onto the metal slug, which is positioned in a die cavity. The forceful impact propels the slug to flow and conform to the contours of the die, producing intricate geometries and high-strength parts in a single stroke. Once the forming operation is complete, an ejector removes the finished part from the die, readying it for subsequent operations or direct application.

How Does Impact Extrusion Work?

The impact extrusion process is distinguished by its cold working technique, meaning the metal is deformed at room temperature, without the need for pre-heating. This results in improved material properties, such as increased hardness and refined grain structure, making it ideal for producing components where durability and precision are critical. The process is particularly advantageous for manufacturing hollow parts, such as tubes, cans, sleeves, and enclosures, with consistent wall thickness and smooth surface finishes.

Extrusion Processes: Types and Methods

Extrusion, and specifically cold extrusion, involves forcing metal to flow plastically through a die under high pressure. Depending on the direction of material flow relative to the punch movement, there are three main extrusion process types:

- Forward Extrusion: The material is forced in the same direction as the punch movement.

- Backward (Reverse) Extrusion: The material flows in the opposite direction to punch travel, enveloping the punch.

- Combined Extrusions: Both forward and backward extrusion methods are applied simultaneously or sequentially to optimize form complexity, strength, and production efficiency.

Forward Extrusions

In forward impact extrusion, the punch drives the metal slug through a die opening, resulting in a part with a reduced cross-sectional area compared to the original billet. This technique enables area reductions of up to 75%, making it highly suitable for forming elongated metal parts such as tubes, rods, and fasteners with high material utilization and minimal waste.

What Types of Parts Benefit from Forward Extrusion?

Common applications include:

- Automotive shafts and axles

- Electrical connectors and terminals

- Aluminum cans and containers

- Metal sleeves and spacers

Backward Extrusions

In backward (or reverse) impact extrusion, the metal is forced to flow around the punch and back towards the press, creating hollow forms such as cups, cases, and enclosures. This method is ideal for producing parts with blind holes or closed ends. Typical area reductions range from 20% to 75%, and the process enables excellent dimensional control for internal and external part features.

When Should You Use Backward Extrusion?

This technique is preferred for manufacturing:

- Aerosol cans and cartridges

- Batteries and battery casings

- Precision sleeves and bushings

- Protective enclosures for electronics

Combined Extrusions

Combined extrusion processes leverage both forward and backward extrusion within a single stroke or multiple sequential operations. The design flexibility offered by combined extrusion allows engineers to create parts with varying wall thicknesses, complex profiles, and integrated features—often reducing the need for secondary operations such as machining or welding. As a result, combined impact extrusion delivers significant cost savings and enhances part performance in demanding applications.

Which Industries Use Combined Impact Extrusion?

Combined techniques are extensively used in:

- Automotive component manufacturing

- Consumer electronics housings

- Industrial fasteners and fittings

- Medical device components

Impact Extrusion in Present-Day Manufacturing

Today, impact extrusion is at the core of advanced manufacturing across automotive, aerospace, electronics, packaging, and consumer goods industries. The process is especially valued for its ability to produce high-precision, lightweight, and structurally robust components at scale. Manufacturers turn to impact extrusion when they require:

- Complex Geometries: The process accommodates intricate internal and external shapes, enabling the production of parts with variable wall thickness, multi-diameter sections, and integrated features.

- Symmetrical and Non-Circular Parts: Although the process is often associated with circular cross-sections, impact extrusion can also form non-round but axis-symmetrical shapes, expanding design possibilities.

- Flange Formation: Flanges of different diameters and profiles can be incorporated along the length of extruded parts for enhanced assembly and performance characteristics.

- Hollow and Solid Forms: Both hollow tubes (with closed or open ends) and solid rods can be efficiently produced, supporting a wide array of applications.

Post-Processing and Secondary Operations

While impact extrusion delivers near-net-shape parts with high dimensional accuracy, certain applications may require additional finishing steps, such as:

- Machining: For tight tolerances or specialized features

- Ironing: To achieve even thinner, uniform wall thickness

- Heat Treatment: For enhanced mechanical properties

- Surface Finishing: Anodizing, plating, or painting for corrosion resistance and appearance

Key Applications of Impact Extrusion

Impact extrusion technology is integral to the mass production of:

- Automotive Parts: Chassis components, shock absorber cylinders, and lightweight brackets

- Consumer Packaging: Aluminum aerosol cans, toothpaste tubes, and food containers

- Industrial Fasteners: Screws, bolts, nuts, and specialty connectors

- Electrical Components: Connectors, battery housings, and protective casings

- Medical Devices: Hypodermic needle barrels, implant housings, and precision surgical tools

Search-Style Prompts for Buyers and Engineers

- What is the difference between impact extrusion and deep drawing?

- How do I determine if my component is suitable for impact extrusion?

- What are the material options for impact extrusion?

- How does impact extrusion compare to traditional metal forming methods in terms of cost and performance?

- Where can I find custom impact extrusion suppliers for aluminum or steel parts?

- What are the tolerances achievable with impact extrusion manufacturing?

Advantages of Impact Extrusion

- Cold-Working Efficiency: As a cold extrusion process, impact extrusion eliminates the need for pre-heating, reducing energy consumption and streamlining production workflows. The process utilizes the enhanced force of modern press systems to plastically deform metals at ambient temperatures, preserving material integrity and mechanical properties.

- Single-Stroke Productivity: Unlike many other forming or extrusion methods, impact extrusion shapes the workpiece in a single, high-speed impact. This dramatically increases throughput, minimizes cycle times, and supports high-volume manufacturing environments.

- Material Utilization and Reduced Waste: With near-net-shape forming, material scrap is minimized, resulting in cost savings, improved sustainability, and reduced post-processing requirements.

- Superior Surface Finish and Precision: The process delivers parts with fine surface finishes and tight dimensional tolerances—often eliminating or reducing the need for additional machining or finishing operations.

- Enhanced Mechanical Properties: Cold working refines the material’s grain structure, imparting increased strength and hardness to the finished part. This makes impact-extruded components ideal for high-stress or wear-critical applications.

- Versatility in Materials and Shapes: Impact extrusion is compatible with a range of metals, including aluminum, copper, steel, brass, and select alloys. The process also supports a wide variety of shapes, from simple cylinders to complex, multi-diameter geometries with flanges or recesses.

- Cost-Effective Tooling and Long Tool Life: The robust tools used in impact extrusion typically offer extended service life, reducing downtime and maintenance costs. Tooling investments are further offset by the high output rates and consistent part quality.

- Corrosion Resistance and Grain Alignment: Parts made by impact extrusion often exhibit superior corrosion resistance and optimal grain alignment, enhancing their longevity, structural integrity, and performance in demanding environments.

- Lightweight End Products: Particularly when working with aluminum alloys, impact extrusion supports the production of lightweight components without sacrificing strength—critical for automotive, aerospace, and portable electronics applications.

- Minimal Need for Secondary Machining: Many impact-extruded items require little to no machining after forming, which shortens production timelines and further reduces costs.

Why Choose Impact Extrusion Over Competing Technologies?

When comparing impact extrusion to methods like deep drawing, hot forging, or traditional machining, several key differences emerge. Impact extrusion provides faster production cycles, better material utilization, and improved part performance—especially for hollow, symmetrical, or thin-walled components. It is often the preferred choice for high-volume production where consistency, repeatability, and cost control are essential.

Impact Extrusion Materials: Selection and Considerations

The choice of material is a critical factor in impact extrusion success. Commonly extruded metals include:

- Aluminum and Aluminum Alloys: Widely used for their light weight, corrosion resistance, and excellent formability. Ideal for packaging, automotive, and consumer electronics parts.

- Steel and Stainless Steel: Selected for applications requiring high strength and durability, such as automotive chassis and industrial fasteners.

- Copper and Brass: Used for electrical and plumbing components due to superior conductivity and corrosion resistance.

- Specialty Alloys: For critical aerospace, medical, or electronics applications requiring unique mechanical or chemical properties.

When evaluating materials, consider factors such as desired mechanical properties, corrosion resistance, part geometry complexity, production volume, and downstream processing requirements.

Frequently Asked Questions About Impact Extrusion

- What tolerances are achievable with impact extrusion?

Typical tolerances range from ±0.05mm to ±0.2mm, depending on material, part size, and complexity. Advanced tooling can deliver even tighter tolerances for precision applications. - Can impact extrusion produce threads or knurled surfaces?

Yes, by designing the die with specific patterns, external threads, knurls, or surface textures can be imparted during the extrusion stroke. - How does impact extrusion compare to deep drawing?

Impact extrusion is generally faster, produces less waste, and achieves superior mechanical properties for symmetrical, hollow, or tubular parts. Deep drawing is better suited for larger, open shapes where wall thickness uniformity is critical. - What is the typical production volume for impact extrusion?

Impact extrusion is ideal for medium to high-volume production runs, thanks to its rapid cycle times and cost-effective tooling. - Can you customize impact-extruded parts?

Absolutely. Custom dies and punches allow for a vast range of part geometries, dimensions, and integrated features to suit specific application needs.

Choosing the Right Impact Extrusion Supplier

Selecting the best impact extrusion partner is essential for achieving optimal performance, cost efficiency, and consistent quality in your finished parts. When sourcing impact extrusion services or products, consider the following factors:

- Experience and Technical Expertise: Look for suppliers with a track record in your target industry—automotive, aerospace, electronics, or packaging—and proven capabilities in cold forming, die design, and process optimization.

- Material Capabilities: Verify that the supplier can handle the specific metals and alloys required for your project, including aluminum, steel, copper, and specialty alloys.

- Production Capacity and Lead Times: Ensure the manufacturer can accommodate your volume requirements and deliver parts on schedule—especially for just-in-time or lean manufacturing operations.

- Quality Assurance and Certifications: Prioritize suppliers with robust quality management systems (ISO 9001, IATF 16949, etc.) and a commitment to in-process inspection, traceability, and continuous improvement.

- Tooling and Engineering Support: Choose a partner offering in-house tool design, prototyping, and engineering collaboration to accelerate development and ensure manufacturability.

- Value-Added Services: Consider suppliers who can provide secondary operations—machining, finishing, assembly, or packaging—to streamline your supply chain.

To make sure you have the most positive outcome when purchasing impact extrusion from an impact extrusion company, it is important to compare at least 6 companies using our list of impact extrusion suppliers. Each impact extrusion supplier has a business profile page that highlights their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each impact extrusion business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple impact extrusion businesses with the same quote request.

Ready to Source Impact Extrusion Services?

Get started: Request a quote from leading impact extrusion manufacturers for your next project. Compare capabilities, lead times, and pricing to ensure the best fit for your production needs.

Explore More About Metal Forming and Extrusion Technologies

For further information, technical assistance, or to discuss complex impact extrusion requirements, contact our team of metal forming experts today.

Cold Headed Parts

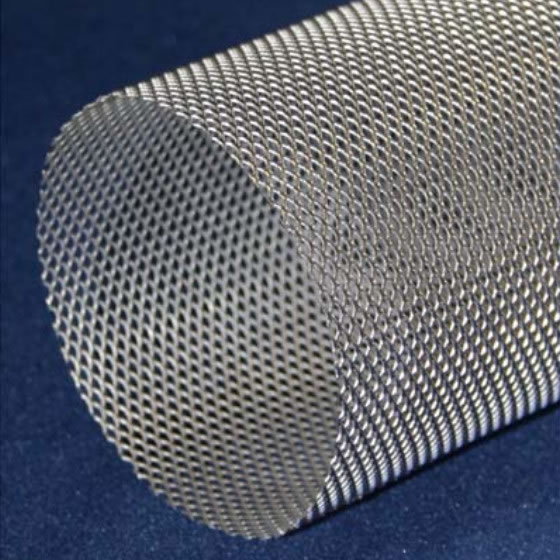

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services