The metalworking procedure known as “cold forming” uses a die to shape, bend, or weld metal without heating it. Metal components are bent into desired forms using high-pressure dies while retaining their original length, width, and thickness (flatness). Since no heating process is involved, cold-formed components typically have more exact dimensions. They can sometimes be made in sizes as small as a few millimeters since the metal formed won’t expand or contract which can occur from the heat used in hot forming. Read More…

At Chicago Nut & Bolt, we specialize in manufacturing high-quality cold headed parts tailored to meet the most demanding industrial specifications. With decades of experience in fastener production, we have built a reputation for delivering precision-engineered components that perform reliably in critical applications.

Global manufacturer Stalcop specializes in the manufacturing of cold headed parts. Stalcop can meet your needs with specialty solutions, combining processes with secondary operations such as CNC machining and assembly. With over 100 years combined experience, count Stalcop for quality and lower prices! Stalcop serves its customers by offering products and services that are consistent and timely.

At Precision Metal Components, we specialize in manufacturing high-performance cold headed parts that deliver superior strength, precision, and reliability across demanding industries. Through advanced cold heading technology, we shape metal with exacting accuracy while minimizing material waste and improving structural integrity.

Here at NSK Industries, Inc. we are a turnkey manufacturing which means we will supply your cold forming needs with a short amount of lead time. Our company manages four facilities and we strive to be an unsurpassed supplier. We have the background and production lines that can get your projects done regardless of complexity. We are eager to adhere to your specifications. Please visit our website ...

More Cold Forming Manufacturers

In cold forming, metal is pressed past its elastic (yield) limit and keeps its distorted shape after being released from the die. If the metal were pulled beyond its tensile strength, it would fracture. Cold forming was first performed in response to the California Gold Rush (1849) and provided miners with the opportunity to buy inexpensive, prefabricated metal housing. Cold forming has traditionally been considered an experimental method, but as new computer-based analytical tools are continuously produced, this is changing.

Basic Cold-Forming Procedures

There are three unique cold-forming processes available to create items. Which procedure is used depends on the part being made.

Forward Extrusion

Forward extrusion is used to create solid items. Using the forward extrusion method to lower the diameter, the material flows freely until it gets trapped in a die.

Backward Extrusion

Backward extrusion is performed to create hollow objects. Under this process, material flows backward around a penetrating punch

Upset Extrusion

Under upset extrusion, material is deformed (upset) at the die face where it can create either solid or hollow shapes. Upset extrusion is used to create longer parts that need only one end to be shaped.

Cold Forming Machinery

A horizontal press is commonly used for cold forming. This press feeds wire, cuts it to the right length, and then feeds it through a succession of tools and dies to shape the material into the desired shape. Depending on the kind of parts that need to be produced, there are numerous variants in machines, including:

- Cutoff diameter capabilities (ranges from 2mm to 48mm (nearly 2”))

- Feed length capabilities (2mm to 300mm (nearly a foot) and beyond)

Materials for Cold Forming

Almost any kind of metal part may be produced using the cold forming technique, but each metal has advantages and disadvantages of its own. With regular die maintenance, it is common to use steel, carbon steel, brass, lead, bronze, precious metals, aluminum, nickel alloys, stainless steel, steel alloys, and other specially-blended materials. Copper, brass, and aluminum are softer materials that can be easily cold-molded.

Advantages of Cold Forming

Cold forming, also known as cold forging, is substantially less expensive and environmentally-friendly than hot forming since it does not require heating the metal to extremely high temperatures.

Precision cold-forming technology has been around for a while. Still, it's becoming increasingly popular due to its capacity to save costs, boost productivity, and enhance product quality while being ecologically friendly.

The complexity of the designs it can produce—such as various surface profiles—cannot be achieved by standard forging techniques, which increases productivity by minimizing equipment duplication.

Mechanical qualities are improved, and the strength-to-weight ratio is increased.

- Lower Production Costs: Cold forming uses precisely-constructed dies and requires less energy input than other processes that employ high temperatures to shape metal components. As a result, cold forming lowers production costs. Therefore, whether traditional or modern technologies are used, cold forming enables faster production rates and increased productivity.

- Material Savings: Since there is no possibility of overheating the raw materials, which results in material waste, inefficiency, and less accurate dimensional tolerance, improved yields from the original materials are added to the savings realized through reduced material waste/scrap during manufacturing.

- Environmentally-Friendly: Precision cold forming is the perfect method for environmentally-aware enterprises since it produces less waste, uses less energy, and costs less money overall. An artificial atmosphere doesn’t need to be created for precision cold forming.

- Near Net-Final Shape: Cold forming is a technique that requires almost no machining to produce nearly net-final dimensions.

- Dimensional accuracy, surface quality (smoothness), regulated geometry, and electrical performance characteristics are further advantages of cold forming.

- Secondary Operations Reduced or Eliminated: Cold forming helps eliminate the need for secondary procedures like welding, punching, and blanking which results in decreased material utilization and shortened lead times.

- Improved Strength and Toughness: When compared to products formed using conventional procedures, cold-worked components have improved tensile strength and toughness because they have different metallurgical properties from those generated by hot-swaging processes. As a result, precise cold-formed parts need less maintenance, which increases the lifespan of mechanical systems like machines and gears.

Disadvantages of Cold Forming

Although cold forming is an excellent method for many applications, cold forming does have its limits that one should be made aware of, such as:

- Size Restrictions: More force is required to press material into the correct shape the larger the fastener's diameter. Any size of fastener can be produced with a large enough machine. However, this is frequently impractical, necessitating the hot forging of some incredibly- big pieces.

- Shape Restrictions: Even though cold-forming technology has advanced over time, some specialty parts with unusual shapes still require material cutting to be created. As a result, these unusual forms are better suited for machining.

Choosing the Correct Cold Forming Company

To make sure you have the most positive outcome when purchasing Cold Forming from a Cold Forming Supplier, it is important to compare at least 5 or 6 Companies using our Cold Forming directory. Each Cold Forming Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Cold Forming business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Cold Forming businesses with the same message.

Cold Headed Parts

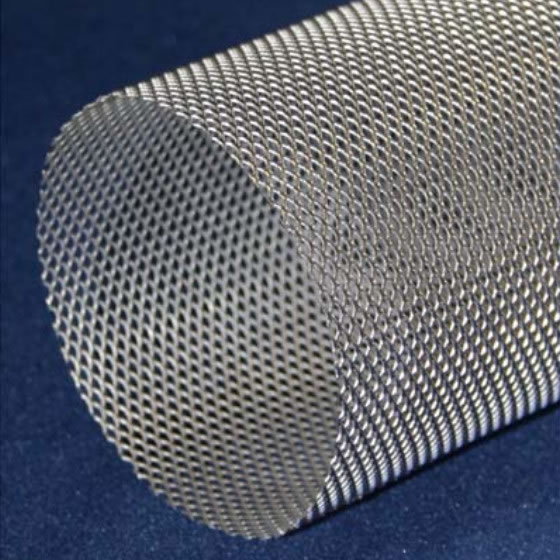

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services