Cold formed parts are metal parts formed using any cold working process. Cold headed parts are a specific type of cold formed metal part; all cold headed parts feature an enlarged section on one end. To create cold headed parts, manufacturers use cold heading, a specialized technique that falls within the broader category of manufacturing known as cold forming. Read More…

At Chicago Nut & Bolt, we specialize in manufacturing high-quality cold headed parts tailored to meet the most demanding industrial specifications. With decades of experience in fastener production, we have built a reputation for delivering precision-engineered components that perform reliably in critical applications.

Global manufacturer Stalcop specializes in the manufacturing of cold headed parts. Stalcop can meet your needs with specialty solutions, combining processes with secondary operations such as CNC machining and assembly. With over 100 years combined experience, count Stalcop for quality and lower prices! Stalcop serves its customers by offering products and services that are consistent and timely.

At Precision Metal Components, we specialize in manufacturing high-performance cold headed parts that deliver superior strength, precision, and reliability across demanding industries. Through advanced cold heading technology, we shape metal with exacting accuracy while minimizing material waste and improving structural integrity.

Here at NSK Industries, Inc. we are a turnkey manufacturing which means we will supply your cold forming needs with a short amount of lead time. Our company manages four facilities and we strive to be an unsurpassed supplier. We have the background and production lines that can get your projects done regardless of complexity. We are eager to adhere to your specifications. Please visit our website ...

More Cold Headed Parts Manufacturers

What are Cold Formed Parts?

Cold-formed parts, also known as cold headed parts or cold forged parts, are precision-engineered components shaped from metal at or near room temperature—without the application of heat—through robust manufacturing processes such as pressing, stamping, rolling, or bending. Unlike traditional hot forming, which involves heating the metal to increase malleability, cold forming harnesses mechanical force to reshape the metal, capitalizing on the material’s inherent ductility and work-hardening properties. This manufacturing method is a staple in high-volume industrial production due to its outstanding efficiency, superior precision, and material utilization benefits.

How Does Cold Forming Work?

The cold forming process begins with high-quality metal stock such as sheets, strips, rods, or wire, commonly made from steel, stainless steel, aluminum, copper, or brass alloys. Automated or semi-automated machines—including powerful presses, multi-die headers, and roll formers—apply concentrated high pressure, often exceeding 100,000 psi, to force the metal into custom-engineered dies or molds. This action deforms the metal into specific shapes, such as fasteners, brackets, connectors, or tubular profiles.

As the metal is cold formed, it undergoes a process known as work hardening. This aligns the metal’s grain structure, significantly increasing its strength and yield properties, though with a tradeoff of reduced ductility if not properly managed. In some cases, parts may require subsequent annealing (controlled heating) to restore ductility for further shaping or stress relief.

Key Examples of Cold Formed Parts

- Fasteners: Screws, bolts, and rivets are typically manufactured via cold heading, where wire is precisely cut and formed under high pressure to create heads and threads in rapid succession.

- Automotive Parts: Clips, brackets, pins, small gears, and spacers are stamped or pressed from sheet metal for use in engines, transmissions, chassis assemblies, and more.

- Construction Components: Steel studs, joists, channels, and framing elements are roll-formed into precise profiles for buildings, bridges, and infrastructure projects.

- Electronics: Connector pins, terminals, shields, and enclosures are cold-formed to meet tight tolerances required in consumer electronics, telecommunications, and computer hardware.

Advantages of Cold Formed Parts

- High Strength: Work hardening during deformation increases tensile and yield strength—cold-formed steel can achieve 20–30% higher yield strength compared to hot-formed metals, enabling robust and reliable end products.

- Exceptional Precision: Tight tolerances (as fine as ±0.001 inches) are possible, making cold formed parts ideal for demanding applications in automotive, aerospace, electronics, and medical sectors.

- Production Efficiency: Cold forming eliminates the need for heating, resulting in rapid cycle times—up to 1,000 parts per minute for fastener production—while reducing energy consumption and overall manufacturing costs.

- Material Savings: Near-net-shape forming minimizes material waste compared to traditional machining or casting. This leads to sustainable, cost-effective manufacturing with minimal scrap.

- Superior Surface Finish: The cold process naturally produces smooth surface finishes, often eliminating the need for secondary polishing or finishing processes.

Drawbacks and Considerations

- Material and Shape Limitations: The process is best suited for ductile metals and simpler part geometries. Extremely complex or brittle materials may crack or fail during forming.

- Upfront Tooling Costs: High-precision dies and tools require significant initial investment, though these costs are amortized over large production runs.

- Residual Stresses: Cold forming can leave internal stresses in parts, sometimes necessitating post-process stress-relief or annealing treatments to ensure long-term performance.

Industry Impact and Market Trends

Cold forming dominates sectors where high-volume production, superior strength, and precision are required. According to a 2023 SME report, cold forming accounts for approximately 70% of global fastener production, with the U.S. market valued at over $15 billion. Cold headed and cold formed parts are integral to modern manufacturing, appearing in everything from automotive drive trains and aerospace assemblies to construction frameworks and consumer electronics.

Are you interested in learning how cold formed parts can solve your manufacturing challenges or reduce your costs? Browse our list of cold headed parts manufacturers or contact us for guidance tailored to your project needs.

Applications and Products

Cold headed production is a foundational cold forming process used across a wide spectrum of industries, offering unparalleled versatility and manufacturing efficiency. Buyers seeking custom cold headed parts will find solutions for virtually every sector:

- Automotive Industry: Cold headed fasteners such as bolts, screws, and rivets are essential for vehicle assembly. The process is also crucial for producing engine and transmission components, steering and suspension parts, bushings, spacers, and electrical connectors. Cold headed parts offer the reliability and precision required for safety-critical automotive systems.

- Aerospace Sector: Aircraft fasteners, landing gear assemblies, actuator components, and control system hardware are often cold headed to meet rigorous strength, fatigue, and safety requirements. The process enables the manufacture of lightweight, high-performance parts that comply with aerospace standards such as AS9100 and NADCAP.

- Electronics Manufacturing: Cold forming is used to produce high-precision connectors, pins, terminals, and shielding components for smartphones, computers, telecommunications, and industrial control systems. Dimensional accuracy and electrical conductivity are essential benefits provided by cold heading in this sector.

- Construction and Infrastructure: Structural connectors, anchors, hinges, hardware, and framing elements are cold headed for durability, uniformity, and cost-effectiveness. Cold heading allows for the rapid, mass production of steel studs, beams, and other building components.

- Medical Device Manufacturing: Cold heading is employed to produce surgical instruments, orthopedic implants, dental devices, and specialized fasteners for medical equipment. The process delivers biocompatibility, corrosion resistance, and tight tolerances crucial for medical applications.

- Consumer Goods: Everyday items such as hand tools, zippers, watches, kitchen appliances, and sporting goods often incorporate cold headed or cold formed metal components for enhanced durability and aesthetics.

Cold heading and cold forming offer high-quality, cost-effective solutions for manufacturing complex, precision metal parts in large quantities. These processes are commonly chosen for their high repeatability, tight quality control, and the ability to integrate seamlessly into automated production lines.

What is the History of Cold Formed Parts?

The evolution of cold-formed parts is a testament to centuries of metallurgical innovation, driven by the quest for more efficient, precise, and scalable metalworking techniques. Below is a detailed timeline illustrating how cold forming transformed from primitive craftsmanship to a backbone of modern manufacturing:

Ancient Origins (Prehistory–Middle Ages)

Cold forming traces its roots to early metallurgy, with evidence dating as far back as 4000 BCE. Ancient Sumerians hammered naturally ductile copper into tools and ornaments at ambient temperatures. By 1200 BCE, artisans of the Bronze Age refined cold working techniques to craft jewelry and weaponry through hammering and shaping, despite the challenges posed by less ductile metals like iron. Around 600 BCE, the Lydians of modern Turkey pioneered coining—pressing metal into dies to mint currency—a foundational cold forming process.

Medieval to Early Modern Era (500–1700s)

During the Middle Ages, craftspeople such as goldsmiths and silversmiths advanced cold forming with techniques like planishing and repoussé. The 16th century introduced water-powered trip hammers, amplifying productive force for forming armor and utensils. John Hanbury’s 1697 patent for a cold-rolling process in England set the stage for industrial-scale cold forming, producing thin iron sheets for broad commercial application.

Industrial Revolution (1800s)

The 19th century marked a pivotal shift. Steam-powered presses and rolling mills enabled mass production of cold-formed steel with unprecedented strength and surface finish. Henry Maudslay’s 1817 screw-cutting lathe and Thomas Sloan’s 1841 nail-making machine patents revolutionized fastener manufacturing. Stamping presses and improved rolling mills drove cold-formed components into widespread use in construction, transportation, and consumer goods.

Early 20th Century (1900s–1940s)

Advancements in electrical and precision engineering accelerated the growth of cold forming. The National Machinery Company (USA) developed early cold heading machines in 1905 to meet the booming demand for automotive fasteners, notably for the Ford Model T. World War I and II spurred further innovation, with cold-formed rivets, shell casings, and lightweight aircraft parts supporting military and industrial expansion. John Tinnerman’s “A-speed nut” fastener in 1936 exemplified the era’s innovation.

Modern Era (1950s–Present)

Postwar, the proliferation of hydraulic presses, multi-station cold headers (e.g., Sacma, Italy), and advanced steel alloys further advanced cold forming capabilities. The 1960s and beyond saw the integration of computer numerical control (CNC) for precision manufacturing, enabling the production of complex aerospace and electronics components. By the 1980s, roll-formed steel studs became standard in construction. Today, cold forming is integral to industries ranging from automotive and aerospace to renewable energy and microelectronics, continually evolving with new materials and micro-forming technology.

Want to explore the history of cold forming in more detail or discover how historical processes shape modern manufacturing? Learn more from our industry resources.

Process Details: How Are Cold Headed Parts Made?

The cold heading process encompasses several key stages, transforming raw metal into precision finished components. Understanding each stage helps buyers and engineers evaluate suppliers and optimize product design:

- Material Selection: The process starts with selecting metals based on required properties—carbon steel for strength, stainless steel for corrosion resistance, aluminum for weight savings, or brass/copper alloys for conductivity.

- Wire or Blank Preparation: Raw material is supplied as wire coils or rod stock, which is straightened and cut to precise lengths to form blanks.

- Feeding and Forming: The blanks are fed into a cold heading machine, where powerful dies and punches, arranged in succession, deform the metal through multiple stages. Processes such as upsetting (creating heads), extrusion (lengthening or forming shafts), coining (adding features), or bending may be performed in sequence.

- Trimming and Separation: Excess material is removed via shearing, cutting, or punching, and the finished part is separated from the remaining feedstock.

- Secondary Operations: Depending on the application, cold headed parts may undergo heat treatment (to optimize hardness or ductility), surface finishing (plating, coating, passivation), or additional machining (threading, drilling) to meet exact specifications.

Cold heading is a high-speed, automated process, offering high repeatability and low per-part cost for large production runs. This makes it a go-to method for manufacturing millions of identical components with tight tolerances and minimal waste.

Have questions about the optimal process for your part or how to specify dimensions and tolerances? Contact our engineering support team for expert guidance.

Design Considerations for Cold Headed Parts

Effective cold headed part design requires careful attention to a range of factors that directly impact manufacturability, performance, and cost:

- Corrosion Resistance: Parts exposed to moisture, chemicals, or extreme conditions require corrosion-resistant materials or protective coatings, such as stainless steel, zinc plating, or specialty finishes.

- Dimensional Requirements: Cold heading excels at producing parts with tight tolerances, but design must account for allowable tolerances, thread sizes, undercuts, and overall geometry to ensure compatibility with downstream assemblies.

- Complexity: While cold heading can create multi-featured components, designs with extremely thin walls, sharp corners, or intricate asymmetrical features may pose challenges and require process modifications or secondary operations.

- Industry Standards: Adherence to standards such as ISO, DIN, ASTM, or sector-specific requirements (e.g., automotive TS16949, medical ISO 13485) ensures quality, performance, and compliance.

- Production Volume: Cold heading is best suited for medium to high production volumes. Tooling and setup costs are offset by the cost savings realized in large batch production.

By aligning material selection, part geometry, and process capability, manufacturers can ensure that their cold headed parts achieve the desired strength, durability, and cost targets.

Do you need help with part design or material selection for cold headed components? Consult our network of experienced cold forging engineers.

What Machines Are Used to Create Cold Formed Parts?

Cold formed parts are manufactured using a suite of specialized cold working equipment designed for high-speed, high-precision metal forming. Key machinery includes:

- Cold Heading Machines:

- Purpose: Form heads and threads on fasteners (bolts, screws, rivets) from wire or rod stock.

- Operation: Metal wire is fed, cut to length, and struck by a punch into a die—often in several stages for complex features. High production rates (300–1,000 parts per minute) are possible with multi-station headers.

- Applications: Automotive fasteners, industrial bolts, construction screws.

- Stamping Presses:

- Purpose: Shape flat sheet metal into brackets, clips, and enclosures via punching, bending, or drawing.

- Operation: Hydraulic or mechanical presses (ranging from 10–10,000 tons) force metal into dies. Progressive dies allow multiple operations in one pass.

- Applications: Appliance fittings, automotive panels.

- Roll Forming Machines:

- Purpose: Create long profiles (steel studs, channels, tubes) from coiled sheet metal.

- Operation: Metal passes through sets of rollers, each incrementally forming the final profile. Custom roller designs enable a wide variety of shapes.

- Applications: Construction framing, roofing panels.

- Press Brakes:

- Purpose: Bend sheet metal into angles or U/V-profiles.

- Operation: A punch presses metal into a die, with CNC controls for precision.

- Applications: Brackets, enclosures, panels.

- Cold Extrusion Presses:

- Purpose: Force metal through a die to produce rods, tubes, or complex shapes.

- Operation: Billets are squeezed under extreme pressure, often lubricated to reduce friction.

- Applications: Gear blanks, aluminum tubes, splined shafts.

- CNC Punch Presses:

- Purpose: Precision cutting and forming of sheet metal, often for complex or perforated parts.

- Operation: Turret-style punches controlled by CNC software automate patterning and forming.

- Applications: Electronics enclosures, decorative panels.

Supporting technologies include custom dies and tooling (often made from hardened steel or carbide for durability), advanced lubrication systems, and CNC integration for repeatability and precision. The choice of machinery depends on part geometry, material type, production volume, and required tolerances.

Are you evaluating which cold forming machinery is best for your next project? Ask our technical team for equipment comparisons and process recommendations.

Variations and Similar Cold Forming Processes

Cold working encompasses a diverse set of metal forming processes. Understanding the differences can help you select the optimal method for your application:

- Cold Extrusion: Extreme pressure forces metal through pre-shaped dies to form rods, tubes, or profiles. Particularly effective with ductile metals like aluminum or copper. Learn more about cold extrusion.

- Cold Roll Forming: Metal blanks pass through rollers to achieve uniform thickness and shape, making it ideal for long, continuous profiles such as rails, studs, and channels.

- Cold Drawing: Metal is pulled—rather than pushed—through a die to reduce diameter, increase length, and improve surface finish. Common for wire, tubes, and precision rods.

- Orbital Forming (Radial Riveting): An orbiting tool presses into metal, gradually forming heads or shapes. Ideal for fastening, flaring, swaging, or crowning hardware. Explore cold headed fastener applications.

- Cold Forging: Encompasses any process where metal is shaped by compressive force at ambient temperature, often within cavities. Cold heading is a subset of this category.

- Cold Molding: Includes molding processes (such as cold runner injection molding) performed without heat, suitable for certain metals and thermosets.

- Waterjet Cutting: Uses high-pressure jets of water, sometimes with abrasives, to cut metal cleanly and precisely with minimal heat-affected zones. Companies like Cold Jet offer specialized equipment for this purpose.

- Impact Extrusion: Shapes metal using a rapid, forceful punch—often used with soft metals. Find impact extrusion companies.

Each method offers unique advantages for different materials, geometries, and production volumes. Selecting the right process can drastically affect part quality, production efficiency, and cost.

Need help choosing the best cold forming process for your part design? Request a free process evaluation.

Advantages of Cold Forming and Cold Heading

Both consumers and manufacturers benefit from the adoption of cold forming processes over traditional hot forming or machining:

- Lower Production Costs: Cold forming eliminates the need for energy-intensive heating, reducing operational expenses and environmental impact.

- High Efficiency and Speed: Processes like cold heading can produce thousands of parts per hour, with minimal setup and rapid changeover.

- Reduced Waste and Scrap: Near-net-shape forming means less material is removed, minimizing scrap compared to machining or casting. This makes cold forming a more sustainable manufacturing option.

- Enhanced Strength and Durability: Work hardening during cold forming improves tensile strength and fatigue resistance, resulting in robust, long-lasting parts.

- Excellent Surface Finish: Cold formed parts often require little to no secondary finishing, saving time and resources in post-processing.

- Dimensional Accuracy: Consistent temperature control leads to superior dimensional stability and repeatability, critical for high-precision applications.

- Versatility: Cold forming supports a wide range of metals and alloys, enabling the production of everything from tiny micro-fasteners to large structural components.

Cold heading, in particular, is a preferred alternative to screw machining due to faster throughput, less burring, lower costs, and stronger parts.

Curious about how cold forming can improve your bottom line or product quality? See real-world case studies from leading manufacturers.

Limitations and How to Overcome Them

While cold forming offers numerous advantages, manufacturers and engineers should be aware of its inherent limitations—and the strategies available to address them:

- Material Restrictions: Cold forming is best suited for ductile metals; brittle materials like cast iron are prone to cracking. To overcome this, select alloys with appropriate ductility or employ advanced lubrication and die design to enhance formability.

- Complex Geometries: While intricate shapes are possible, extremely thin walls, sharp corners, or deep recesses may require design modification or the use of hybrid manufacturing (combining cold forming with machining or secondary operations).

- Tooling Investment: High cost for custom dies and tools can be a barrier for low-volume or prototype runs. Some suppliers offer modular tooling or rapid prototyping services to mitigate this risk.

- Residual Stresses: Internal stresses can be addressed through stress-relief annealing, optimized forming sequences, or advanced process monitoring.

Manufacturers continually invest in R&D, advanced machine controls, innovative tooling, and material science to expand the range of parts that can be successfully cold formed. Hybrid approaches—such as combining cold forming with selective machining, laser cutting, or additive manufacturing—are increasingly common for complex or low-volume parts.

Wondering if your part can be cold formed, or how to overcome design obstacles? Get a free manufacturability assessment.

Things to Consider When Choosing a Cold Headed Parts Manufacturer

When sourcing cold headed or cold formed parts, selecting the right supplier is critical to ensuring quality, reliability, and value. Here’s a step-by-step approach to streamline your procurement decision:

- Define Your Requirements: Outline your part specifications, including material type, dimensions, tolerances, surface finish, corrosion resistance, and any applicable industry standards. Don’t forget to specify your desired quantity, delivery deadlines, and budget constraints.

- Research Qualified Suppliers: Use online directories, industry associations, or trusted platforms like this one to identify manufacturers equipped with a range of cold working machines, advanced quality control, and a proven track record in your industry.

- Compare Capabilities and Services: Review company profiles, certifications (e.g., ISO 9001, IATF 16949), secondary processing capabilities (heat treating, plating, thread rolling), and value-added services (design assistance, prototyping, logistics support).

- Engage and Evaluate: Contact two or three shortlisted manufacturers to discuss your project in detail. Evaluate their responsiveness, technical expertise, and willingness to provide engineering support or sample parts. Request case studies or references if needed.

- Make an Informed Decision: Choose the manufacturer offering the best combination of technical capability, pricing, lead time, and customer service. Strong supplier partnerships often yield better long-term results in terms of quality, innovation, and cost savings.

Ready to request a quote or compare manufacturers? Browse our curated list of cold headed part suppliers to get started.

For more information, industry insights, or personalized assistance, reach out to our cold forming experts today.

What are cold formed parts?

Cold-formed parts are precision-engineered metal components shaped at or near room temperature using mechanical processes like pressing, stamping, rolling, or bending—without applying heat. This method leverages the metal’s ductility and work-hardening properties, yielding efficient, high-precision, and material-saving production, especially for high-volume industrial applications.

How does cold forming work?

Cold forming starts with metal stock (wire, rods, sheets) fed into automated or semi-automated machines, which apply concentrated pressure to deform the material into dies or molds. This process increases the metal’s strength through work hardening and is used to create shapes like fasteners, brackets, and connectors. Sometimes, annealing is performed after forming to restore ductility.

What are typical applications and products made using cold heading and cold forming?

Cold heading and cold forming are used to manufacture fasteners (bolts, screws, rivets), automotive and aerospace components, electronic connectors, building hardware, medical devices, and consumer goods. These processes offer versatility, dimensional precision, and are ideal for large-batch, high-repeatability production across many industries.

What are the main advantages of cold forming compared to traditional metalworking?

Cold forming delivers high strength through work hardening, exceptional precision, high production efficiency, material savings via near-net-shape forming, and superior surface finish. It also reduces production costs by eliminating the need for heating and minimizes material waste, making it a sustainable and cost-effective manufacturing choice.

What limitations are associated with cold formed parts and how can they be addressed?

Cold forming is best for ductile metals and simpler shapes; brittle materials may crack, and intricate geometries may require design adjustments or secondary operations. High tooling costs can be overcome through large-scale production or modular tooling. Residual stresses can be relieved by annealing or optimized process design.

What machines are used to manufacture cold formed parts?

Cold formed parts are made with equipment like cold heading machines, stamping presses, roll forming machines, press brakes, cold extrusion presses, and CNC punch presses. Supporting technologies include specialized dies, lubrication systems, and CNC controls that ensure precision and repeatability for a wide range of part geometries and volumes.

What should be considered when choosing a cold headed parts manufacturer?

When choosing a manufacturer, evaluate their experience, machine capabilities, certifications (like ISO or IATF), value-added services, quality control, and ability to meet your specifications and volume needs. Comparing multiple suppliers and ensuring open communication will help secure reliable, high-quality parts, and long-term value.

Cold Headed Parts

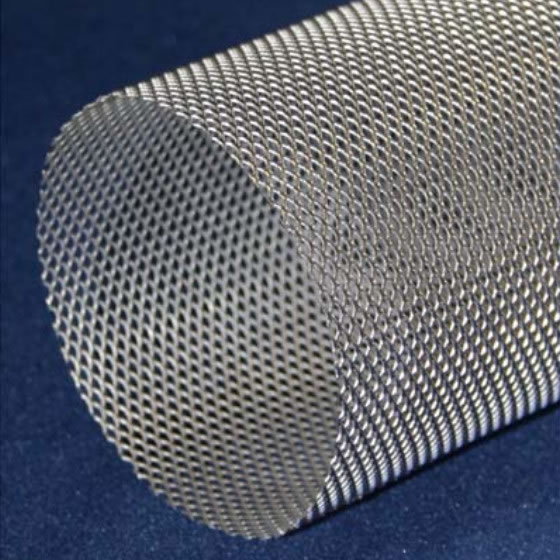

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services