The process of cold heading uses force to shape a metal blank into a shape of a punch and die. The process is called cold forming because the metal is cooler than in many hot forging processes, where the metal is near the melting point during forging. Most cold forged processes still heat the metal some, but the heating process takes place in a separate machine from the punching and die forming process. A cold headed part is formed when the metal’s yield strength is exceeded. When this happens, the material flows into the die, and transforms into that size and shape of object.

Surprisingly enough, cold heading parts can actually produce more precise parts than other parts manufacturing processes. Because of the specific shape of the die, it is possible to create small precision parts without the need for extra machining or tooling. It is possible to make small and complex contacts, rivets, miniature components, electronic components, and electrodes. Cold heading also is cheaper and faster than many other metal forming processes.

Cold Headed Parts

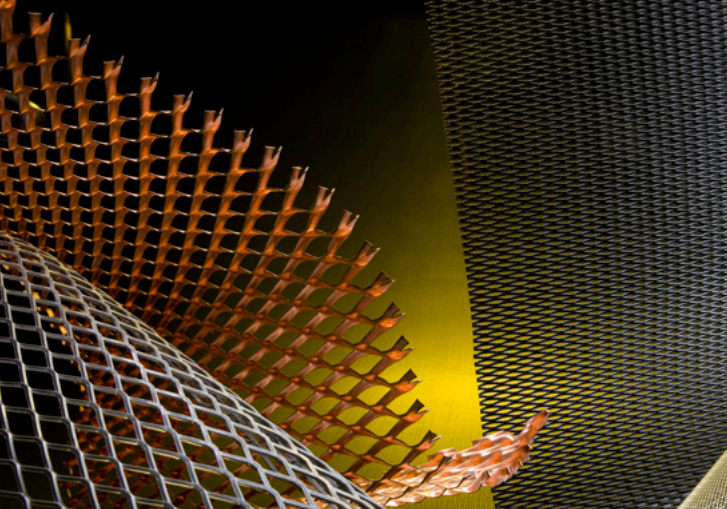

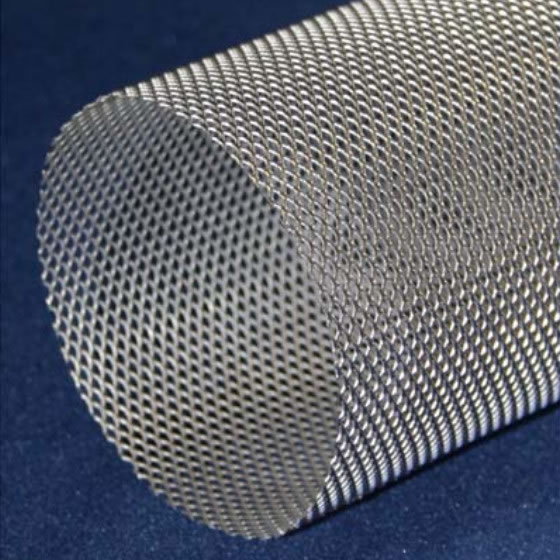

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services